Contact Us

Gehrig® Bearings - Slide bearings

Slide bearings

In addition to roller bearings, slide bearings are the most commonly used bearings in machines, pumps and similar equipment. Sleeve bearings are used wherever space is limited and where the design demands movement that is stable yet flexible and with as little friction as possible. Slide (or sleeve) bearings differ from normal deep groove bearings: slide bearings have two components moving relative to each other, but in direct contact. This causes a certain amount of friction and causes resistance by sliding friction. The coefficient of friction can be kept low by some or all of these factors: a ‘low friction, low-wear’ material pairing, an appropriate surface finish, through careful design, or by lubrication – either by the media itself or by establishing permanent lubrication. It should be borne in mind that when there is direct contact of rotating machine components, wear on the bearing contact surfaces inevitably limits bearing life. A distinction is made between simple plain bearings and hydro-dynamic / hydrostatic bearings - that is to say those with forced lubrication. Attention must be paid to friction, middle bearing pressure, load range (Sommerfeld number*), storage temperature, relative bearing play, buckling sensitivity and risk level. Gehrig® use the same technical ceramics for plain bearing materials as it does for ceramic rolling bearings.

*The Sommerfeld number or bearing characteristic number, is a dimensionless quantity used extensively in hydrodynamic lubrication analysis. The Sommerfeld number is very important in lubrication analysis because it contains all the variables normally specified by the designer. The friction loss in power is calculated from the coefficient of friction, bearing force and circumferential shaft speed.

GL CZ 10x16x10mm MB

Massive full ceramic slide bearing made of ZrO2 ceramic concerning DIN 4379 (DIN 1850-1) as a sleeve with flange. Zirconia ZrO2 ceramic is ideal for components together with steel and has on the basis of its hard surface a good, affordable protection against wear and abrasion.

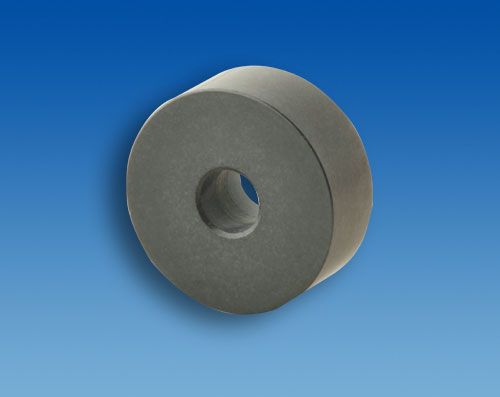

GL CN 5x18x7mm

Massive full ceramic sleeve bearing made of Si3N4 ceramic concerning DIN 4379 (DIN 1850-1) as a friction bearing for guiding wires. Silicon nitride Si3N4 ceramic Si3N4 ceramic takes place through its high mechanical strength and fracture toughness especially for abrasive and high temperature application.

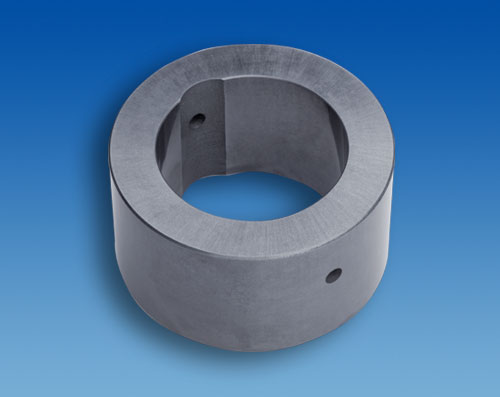

GL CC 50x75x40mm GZ

Full ceramic friction bearing component made of SiC ceramic concerning DIN 4379 (DIN 1850-1) with lubrication hole. Silicon carbide SiC ceramic as a very robust and extremely tough technical ceramics is especially used in the case of strong abrasion and high thermal applications.